My Dad’s Story

By David Ashton

My dad spent his working life in a skilled trade position in a manufacturing environment. He was the type of person that was constantly looking to develop something to make life just a little bit easier. He made a car top boat loader, a pop-up camping trailer and a hand held walk behind “Zamboni” for my backyard ice rink, long before you could ever buy anything like them in a store.

He believed in honest hard work, doing your best, and the concept that if you are going to do something, then it’s worth doing right. So lessons and education were a big part of what he expected when you took on a new hobby or task.

Although a very creative person he was not a very artistic person. In 1988 he finally made the move into retirement and initially found himself with plenty of time on his hands. As a gag gift for his retirement, my wife bought my dad an Exacto wood carvers set. It was a small basic collection of knives for whittling wood. The premise of the gag was, that now you are retired you can sit in a rocking chair on the front porch and whittle a stick.

My dad didn’t get the joke.

He proceeded to search for a wood carving teacher so he could learn the finer points of creating the best carving he could.

He found a very creative young man who, after a work accident, used his passion for carving wood to create lifelike renditions of ducks, songbirds and birds of prey.

I remember being at his house, scared that the hawk in the corner was about to take flight and seek me out as it’s next meal.

Dad studied and worked hard, sometimes carving 8 hours per day trying to perfect his new found craft. He purchased and studied a book entitled, “Drawing On The Right Side Of Your Brain”, to help him improve his artistic ability. He built a small carving shop in the backyard as my mother forced him and his dust producing hobby out of her house.

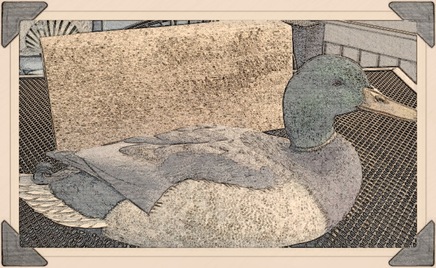

As his passion grew and his carving mechanics improved he developed the ability to produce very lifelike and expressional duck heads. Apparently, in the duck carving world the ability to carve quality heads is a great asset. This inspired him even more and before long dad was turning out some rather impressive carvings. He had reached the point where the need to paint his creations was upon him.

At first he farmed out the painting to another individual as he himself could not paint and produce a realistic rendition of a Mallard. This quickly did not fit Dad’s need to pursue perfection and before long he was waist deep in the art of waterfowl painting. Through practice and hard work he became as good a painter as he was a carver.

So dad was now turning out piece after piece. He would give carvings as gifts for birthday’s, weddings, anniversaries, and whenever he felt you deserved something special. And if his house was getting too full, then carvings made their way to my house. Our house is filled with his work from over the years. He started to branch out into relief carving, song bird carving and busts of ancient Vikings. He carved places that my mom and dad went over the years and anything that he had an interest in. He even carved the street that my parents honeymooned on from a 40 year old picture.

Dad didn’t sell or accept money for any of his carvings. His view was, that if he did it for money then he would start to keep track of the time spent on a piece and that may short cut the level of detail and the overall quality of the carving.

So as time went on the need for increased challenges grew, and one day his teacher convinced him that his work may do well in competition. So dad embarked on creating a carving to enter in the Ward Institute World Carving Championships in Ocean City, Maryland. I suppose if you going to go into something, go big.

Dad has entered this competition 3 times. He has won his class twice and came in third once. All of these pieces sit in my house today as a constant reminder that hard work, doing your best, and the concept that if you are going to do something, then it’s worth doing right, can help you produce great things.

Over the years I have been fortunate enough to witness family, friends, and the general public’s reaction as they see Dad’s carvings for the first time. The reaction is one of amazement around the lifelike quality of the piece. Once the astonished look subsides, it is always followed by the same question.

That is so lifelike, how do you do that?

It is at this point that the door of opportunity has swung open for dad to launch his everlasting carving joke. His immediate response to that question is always:

It’s easy, all you do is carve away everything that doesn’t look like a duck!

I listened to this response hundreds of times, each time thinking, dad stop with the bad pun, it is really getting old. Dad’s response is then followed by a light chuckle from both the admirer and him and then everyone goes on with their business.

I don’t know if my dad is Einstein or Mr. MaGoo, but it took me a very long time (years) to get it. I finally woke up one day with a totally different understanding and appreciation for that never ending bad pun.

All you do is carve away everything that doesn’t look like a duck!

What I had finally come to understand was, that my father has true vision. When he looks at a block of wood he doesn’t see a block of wood, he sees a finished, lifelike, artistically excellent duck that meets his inner standards and creates pride and accomplishment. All that and he hasn’t even started yet.

So I started thinking about my father and others like him who have true vision that is supported by operational excellence and the master pieces they create. I though about Walt Disney, Dr. Martin Luther King Jr., the great painters of history, the great world political leaders, Steven Spielberg, and some of the great inventors. I then start thinking about those companies that really portray operational excellence. Companies like Rolex, Waterford Crystal, Disney Entertainment, Bass Pro Shops, Dell Computers, and Sony. These are some of the companies that have achieved a level of operational excellence: A level of performance that has set them apart from their competition.

Since so few companies achieve operational excellence, there must be an element present in those that do that is not present in those that don’t. Now I grant you that there are hundreds of factors that determine the ability to achieve business success, but the number of people that truly have vision are very few.

I then wondered,

So we did. We took a group of shop floor manufacturing production workers and put them in a room and used a tool we developed called Vision Quest.

Vision Quest starts with an educational session on what operational excellence is: A level of performance that sets you apart from your competition, a level of performance that all others are compared to.

It then creates an environment where each individual sees the task, situation, or space in a state of excellence.

We then give the group a short list of rules and guidelines for the exercise. Vision Quest then requires each person to describe, out loud, the details around their vision of excellence for the topic. These details are then captured to create, on paper, the groups vision of excellence for this specific task or situation. The details are then discussed and a consensus is produced.

Once the vision of excellence is on paper and we have consensus, we then physically take the written vision to the location and compare vision to reality. Any system or behavior that does not fit the vision will then have an action created to help drive the reality closer to the vision.

Carving away anything that doesn’t look like a duck!

The great thing about this tool is that it develops everyone to see things in an operationally excellent light. It can use the vision of the workforce as well as the vision of the management group and each person has ownership and involvement in the improvement process. And when used with an action item format task assignment and accountability system, it will provide performance improvement results that will raise the bar to new heights.

As western manufacturing is struggling to maintain a level of competitiveness in the global market place, leaders are looking for new ways to grab any competitive edge they can. Many are looking to streamline operations and remove layers of support. Many are looking to create a team or collaborative environment. All should be looking to capture the hearts and minds of their workforces. The Vision Quest tool can be one tool that truly moves you closer to your vision.

Be a leader, have vision, pursue excellence, develop your people, enjoy the journey.

So it is time to say thank-you to my Einstein for teaching me the value of having Vision and enabling me to create a tool that has truly developed a new level of excellence in me and in hundreds of managers and floor operators in American business.

Thanks Dad!

© Dave Ashton

Dave is our Vice President of Operations. He leads our "Intensive Care Teams" and develops our Lean Education Series for building understanding of lean thinking and working practice.

By David Ashton

My dad spent his working life in a skilled trade position in a manufacturing environment. He was the type of person that was constantly looking to develop something to make life just a little bit easier. He made a car top boat loader, a pop-up camping trailer and a hand held walk behind “Zamboni” for my backyard ice rink, long before you could ever buy anything like them in a store.

He believed in honest hard work, doing your best, and the concept that if you are going to do something, then it’s worth doing right. So lessons and education were a big part of what he expected when you took on a new hobby or task.

Although a very creative person he was not a very artistic person. In 1988 he finally made the move into retirement and initially found himself with plenty of time on his hands. As a gag gift for his retirement, my wife bought my dad an Exacto wood carvers set. It was a small basic collection of knives for whittling wood. The premise of the gag was, that now you are retired you can sit in a rocking chair on the front porch and whittle a stick.

My dad didn’t get the joke.

He proceeded to search for a wood carving teacher so he could learn the finer points of creating the best carving he could.

He found a very creative young man who, after a work accident, used his passion for carving wood to create lifelike renditions of ducks, songbirds and birds of prey.

I remember being at his house, scared that the hawk in the corner was about to take flight and seek me out as it’s next meal.

Dad studied and worked hard, sometimes carving 8 hours per day trying to perfect his new found craft. He purchased and studied a book entitled, “Drawing On The Right Side Of Your Brain”, to help him improve his artistic ability. He built a small carving shop in the backyard as my mother forced him and his dust producing hobby out of her house.

As his passion grew and his carving mechanics improved he developed the ability to produce very lifelike and expressional duck heads. Apparently, in the duck carving world the ability to carve quality heads is a great asset. This inspired him even more and before long dad was turning out some rather impressive carvings. He had reached the point where the need to paint his creations was upon him.

At first he farmed out the painting to another individual as he himself could not paint and produce a realistic rendition of a Mallard. This quickly did not fit Dad’s need to pursue perfection and before long he was waist deep in the art of waterfowl painting. Through practice and hard work he became as good a painter as he was a carver.

So dad was now turning out piece after piece. He would give carvings as gifts for birthday’s, weddings, anniversaries, and whenever he felt you deserved something special. And if his house was getting too full, then carvings made their way to my house. Our house is filled with his work from over the years. He started to branch out into relief carving, song bird carving and busts of ancient Vikings. He carved places that my mom and dad went over the years and anything that he had an interest in. He even carved the street that my parents honeymooned on from a 40 year old picture.

Dad didn’t sell or accept money for any of his carvings. His view was, that if he did it for money then he would start to keep track of the time spent on a piece and that may short cut the level of detail and the overall quality of the carving.

So as time went on the need for increased challenges grew, and one day his teacher convinced him that his work may do well in competition. So dad embarked on creating a carving to enter in the Ward Institute World Carving Championships in Ocean City, Maryland. I suppose if you going to go into something, go big.

Dad has entered this competition 3 times. He has won his class twice and came in third once. All of these pieces sit in my house today as a constant reminder that hard work, doing your best, and the concept that if you are going to do something, then it’s worth doing right, can help you produce great things.

Over the years I have been fortunate enough to witness family, friends, and the general public’s reaction as they see Dad’s carvings for the first time. The reaction is one of amazement around the lifelike quality of the piece. Once the astonished look subsides, it is always followed by the same question.

That is so lifelike, how do you do that?

It is at this point that the door of opportunity has swung open for dad to launch his everlasting carving joke. His immediate response to that question is always:

It’s easy, all you do is carve away everything that doesn’t look like a duck!

I listened to this response hundreds of times, each time thinking, dad stop with the bad pun, it is really getting old. Dad’s response is then followed by a light chuckle from both the admirer and him and then everyone goes on with their business.

I don’t know if my dad is Einstein or Mr. MaGoo, but it took me a very long time (years) to get it. I finally woke up one day with a totally different understanding and appreciation for that never ending bad pun.

All you do is carve away everything that doesn’t look like a duck!

What I had finally come to understand was, that my father has true vision. When he looks at a block of wood he doesn’t see a block of wood, he sees a finished, lifelike, artistically excellent duck that meets his inner standards and creates pride and accomplishment. All that and he hasn’t even started yet.

So I started thinking about my father and others like him who have true vision that is supported by operational excellence and the master pieces they create. I though about Walt Disney, Dr. Martin Luther King Jr., the great painters of history, the great world political leaders, Steven Spielberg, and some of the great inventors. I then start thinking about those companies that really portray operational excellence. Companies like Rolex, Waterford Crystal, Disney Entertainment, Bass Pro Shops, Dell Computers, and Sony. These are some of the companies that have achieved a level of operational excellence: A level of performance that has set them apart from their competition.

Since so few companies achieve operational excellence, there must be an element present in those that do that is not present in those that don’t. Now I grant you that there are hundreds of factors that determine the ability to achieve business success, but the number of people that truly have vision are very few.

I then wondered,

- Can vision around excellence be developed?

- How can we grow a vision of operational excellence in the people within our organizations?

- Can we develop an environment that will get anyone to stop and think about a topic, situation, or physical space in terms of operational excellence?

So we did. We took a group of shop floor manufacturing production workers and put them in a room and used a tool we developed called Vision Quest.

Vision Quest starts with an educational session on what operational excellence is: A level of performance that sets you apart from your competition, a level of performance that all others are compared to.

It then creates an environment where each individual sees the task, situation, or space in a state of excellence.

We then give the group a short list of rules and guidelines for the exercise. Vision Quest then requires each person to describe, out loud, the details around their vision of excellence for the topic. These details are then captured to create, on paper, the groups vision of excellence for this specific task or situation. The details are then discussed and a consensus is produced.

Once the vision of excellence is on paper and we have consensus, we then physically take the written vision to the location and compare vision to reality. Any system or behavior that does not fit the vision will then have an action created to help drive the reality closer to the vision.

Carving away anything that doesn’t look like a duck!

The great thing about this tool is that it develops everyone to see things in an operationally excellent light. It can use the vision of the workforce as well as the vision of the management group and each person has ownership and involvement in the improvement process. And when used with an action item format task assignment and accountability system, it will provide performance improvement results that will raise the bar to new heights.

As western manufacturing is struggling to maintain a level of competitiveness in the global market place, leaders are looking for new ways to grab any competitive edge they can. Many are looking to streamline operations and remove layers of support. Many are looking to create a team or collaborative environment. All should be looking to capture the hearts and minds of their workforces. The Vision Quest tool can be one tool that truly moves you closer to your vision.

Be a leader, have vision, pursue excellence, develop your people, enjoy the journey.

So it is time to say thank-you to my Einstein for teaching me the value of having Vision and enabling me to create a tool that has truly developed a new level of excellence in me and in hundreds of managers and floor operators in American business.

Thanks Dad!

© Dave Ashton

Dave is our Vice President of Operations. He leads our "Intensive Care Teams" and develops our Lean Education Series for building understanding of lean thinking and working practice.

RSS Feed

RSS Feed